February 4, 2026

What is Refuse Derived Fuel (RDF)?

India’s Waste Problems & WtE (GS Paper 3: Environment & Science)

Context:

The government has recently notified the Solid Waste Management (SWM) Rules, 2026 (notified Jan 2026, effective April 2026), moving India toward a Circular Economy model.

Key Features of SWM Rules 2026:

- Four-Way Segregation: Mandatory sorting into Wet (organic), Dry (recyclable), Sanitary (diapers/masks), and Special Care (hazardous domestic waste) at the source.

- Waste-to-Energy (WtE) Focus: Mandates the use of Refuse Derived Fuel (RDF) in cement plants and thermal power stations. RDF is produced from non-recyclable plastic and textiles with high calorific value.

- Extended Bulk Waste Generator Responsibility (EBWGR): Entities generating >100kg/day or occupying >20,000 sq.m must manage their waste on-site or pay environmental compensation.

- Polluter Pays Principle: Imposes financial penalties for non-segregation and false reporting via a new Centralised Online Tracking Portal.

Challenges :

- Informal Sector Integration: 80% of India’s recycling is done by the informal sector (waste pickers). Rules often fail to provide them with social security.

- Technical Failure of WtE: Many Indian WtE plants fail because “mixed waste” has high moisture and low calorific value, which damages expensive machinery.

- Landfill Legacy: India still has over 3,000 legacy dumpsites (like Ghazipur in Delhi) that emit methane and contaminate groundwater.

About RDF:

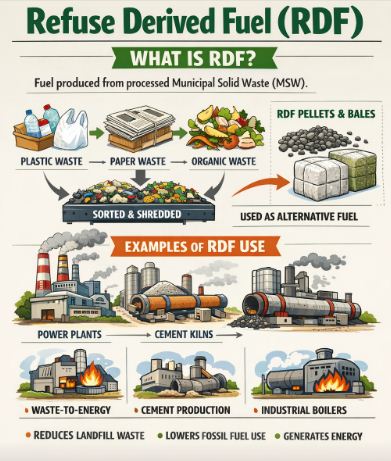

Refuse Derived Fuel (RDF) is a vital component of modern waste management, particularly for UPSC aspirants following the Solid Waste Management (SWM) Rules, 2026. It represents the transformation of “waste to wealth” by converting non-recyclable combustible waste into a high-energy fuel source.

What is RDF?

RDF is a fuel produced by processing various types of municipal solid waste (MSW) to separate the non-combustible materials (glass, metal) from the combustible ones.

- Composition: Primarily consists of non-recyclable plastics, paper, cardboard, textiles, rubber, and wood.

- Calorific Value: Typically ranges from 2,500 to 5,000 kcal/kg, making it a viable alternative to low-grade coal.

The Production Process:

The conversion of raw garbage into RDF involves several mechanical stages:

- Sorting & Screening: Removing inert materials (sand, grit), metals (using magnets), and glass.

- Drying: Reducing moisture content to below 20% to ensure efficient burning.

- Shredding: Breaking waste into a uniform size (usually 30–70 mm).

- Pelletizing (Optional): Compressing the “fluff” into dense pellets or briquettes for easier transport and storage.

October 17, 2025

October 16, 2025

October 6, 2025

September 24, 2025