March 10, 2024

Revival of Penicillin G Manufacturing in India: Reasons for Shutdown and Resumption

Introduction:

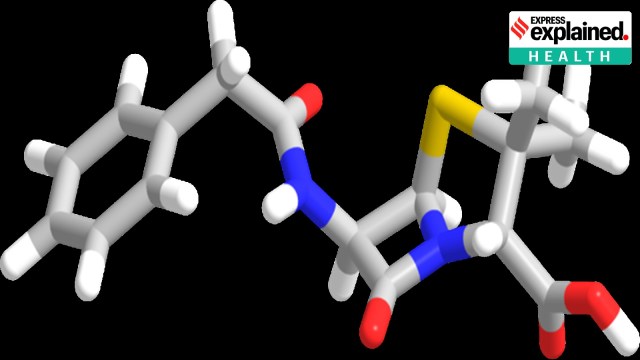

- India is set to resume the production of Penicillin G, a crucial pharmaceutical ingredient for various antibiotics, after a hiatus of three decades. This decision comes as a significant stride in the government’s initiative to bolster domestic manufacturing, particularly in light of disruptions caused by the pandemic.

- The cessation of Penicillin G manufacturing in the 1990s, primarily due to competitive pressures from cheaper Chinese imports, left a void in India’s pharmaceutical landscape. Now, with the revival of production, it’s imperative to understand the factors behind the shutdown and the catalysts driving its resurgence.

Reasons for the Halt in Penicillin G Manufacturing:

- Subsidy-driven Competition from Chinese Products: The discontinuation of Penicillin G production in India stemmed from the inundation of the market with subsidized Chinese alternatives. Cheaper imports rendered local manufacturing economically unviable, leading to the closure of several Indian plants, including Torrent Pharma’s facility in Ahmedabad.

- Market Dynamics and Regulatory Framework: The liberalization of India’s economy in the 1990s, coupled with relaxed customs regulations, further exacerbated the situation. Additionally, regulatory measures such as the Drug Prices Control Order, aimed at controlling medication costs, favored the adoption of cost-effective imported products over domestic manufacturing.

Impact of the Production Linked Incentive (PLI) Scheme:

- Recognition of Supply Chain Vulnerabilities: The disruptions caused by the global pandemic underscored the vulnerabilities in India’s pharmaceutical supply chain, prompting a renewed focus on bolstering domestic production. The government’s introduction of the PLI scheme aimed to incentivize local manufacturing and reduce dependence on imports.

Challenges Hindering Restart:

- High Initial Capital Investment: Reviving Penicillin G manufacturing entails substantial capital expenditure, particularly for setting up fermentation-based production facilities. Companies face a prolonged break-even period, adding to the financial hurdles associated with reestablishing operations.

- Competition from Established Suppliers: China’s entrenched position as a major supplier presents a formidable challenge for Indian manufacturers. Competing with China’s pricing necessitates significant investments in infrastructure and scale, posing additional barriers to restarting production.

Impact of PLI Schemes on Imports:

- Progress in Reducing Dependency: While the PLI scheme has contributed to a decline in API imports, particularly for critical medications like paracetamol, the transition to self-sufficiency remains gradual. Despite notable progress, India continues to rely heavily on imported APIs, indicating the need for sustained efforts to strengthen domestic manufacturing capabilities.

Conclusion:

- The resurgence of Penicillin G manufacturing in India marks a pivotal moment in the country’s pharmaceutical industry. The decision reflects a strategic shift towards bolstering domestic production capabilities and reducing dependency on imports. However, significant challenges, including high initial costs and intense competition, underscore the need for sustained government support and industry collaboration to ensure the long-term viability of domestic manufacturing initiatives.

Llama 3:

April 24, 2024

Global Plastic Treaty:

April 24, 2024

THE WORLD TIGER DAY CELEBRATION

August 5, 2022

A new Sample data for Polity & Governance

July 27, 2022

Sample data for Polity & Governance

July 27, 2022