February 6, 2026

Sodium-ion Batteries (SiB):

Batteries have evolved from simple power sources for gadgets into the foundational pillar of the global economy and clean energy transition.

- Ubiquity: Integrated into everything from wearables and EVs to large-scale grid storage and household appliances.

- Strategic Importance: Critical for economic growth, energy security, and achieving net-zero goals.

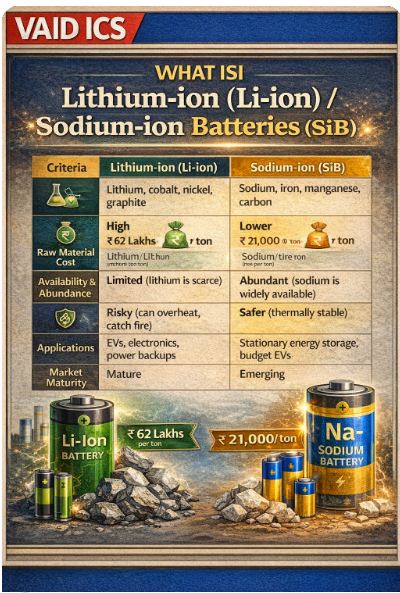

- Lithium-ion (Li-ion) Dominance: * Drivers: High energy density, low self-discharge, and established manufacturing scale.

- Cost Reduction: Prices plummeted from $1,100/kWh (2010s) to roughly $108/kWh by 2025.

Structural Challenges of Lithium-ion:

Despite its dominance, Li-ion technology faces significant “upstream” vulnerabilities:

- Resource Intensity: Heavy reliance on critical minerals like Lithium, Cobalt, Nickel, and Graphite.

- Geopolitical Risk: Mineral reserves and refining capacities are geographically concentrated (e.g., in China, Chile, and DRC), leading to supply chain fragility.

- The India Factor: * While the PLI Scheme (2021) for Advanced Chemistry Cells targets 40 GWh, actual deployment is still in early stages.

- India remains heavily dependent on imports due to a lack of domestic mineral processing and component manufacturing (cathodes, anodes, separators).

Sodium-ion Batteries (SiB): The Strategic Alternative:

Sodium-ion technology offers a structurally different and more resilient pathway for India’s energy future.

A. Performance & Energy Density:

- The Gap: Sodium is heavier than Lithium, leading to lower specific energy (Wh/kg).

- Progress: Layered oxide SiBs are now narrowing the gap and approaching the performance of Lithium Iron Phosphate (LFP)

- Optimization: Ongoing cell-level improvements are expected to make SiBs competitive even for volumetric density (Wh/L).

B. Superior Safety Profile:

- Thermal Stability: SiBs show significantly lower peak temperature rise during “thermal runaway” events compared to Li-ion.

- Transportation Ease: * Li-ion batteries are “Dangerous Goods” and must be shipped at <30% State of Charge (SoC).

- Zero-Volt Storage: SiBs can be safely discharged to 0V for storage and transport without degrading, reducing logistics costs and risks.

C. Manufacturing & Material Advantages:

- Infrastructure Compatibility: Existing Li-ion production lines can be adapted for SiBs with minor modifications (primarily stricter vacuum drying).

- Abundant Materials: Sodium is derived from widely available Soda Ash, eliminating reliance on scarce minerals.

- Aluminum Current Collectors: Unlike Li-ion (which uses copper for the anode), SiBs use Aluminum for both electrodes. Aluminum is cheaper, lighter, and more readily available.

Why Sodium-ion Matters for India?

| Feature | Impact on India |

| Supply Security | Reduces dependence on imported Lithium and Cobalt. |

| Cost Stability | Insulates the economy from global commodity price volatility. |

| Sustainability | Uses abundant, environmentally friendly materials. |

| Economic Scale | Global capacity is expected to reach 400 GWh by 2030. |

Policy & Regulatory Recommendations:

To foster a “future-ready” ecosystem, India should:

- Broaden Incentives: Expand the PLI Framework to explicitly support Sodium-ion chemistry and upstream components (cathodes/anodes).

- Update Standards: Revise safety codes and certification pathways to fast-track SiB commercialization.

- Dual-Approval Strategy: Encourage EV manufacturers to type-test platforms for both Li-ion and SiB to allow rapid substitution during supply shocks.

- Targeted Funding: Provide public R&D funds for stationary grid storage and 2/3-wheeler EV applications.

Gist of daily Article /The Hindu 17oct 2025

October 17, 2025

Daily Gist of the Hindu/Indian Express : 16 Oct 2025

October 16, 2025

Daily Gist of The Hindu/Indian Express: 6 Oct 2025

October 6, 2025

Daily Gist of Article /The Hindu /Indian Express: 24 Sep 2025

September 24, 2025